GM’s EV Truck Production Delay: Implications for Automotive Industry 2023

In light of recent developments, we need to address General Motors’ decision to delay electric vehicle (EV) truck production at its Michigan plant. This unexpected delay has far-reaching implications, not only for GM but for the entire automotive industry.

The Unforeseen Delay

General Motors, a renowned player in the automotive industry, recently announced a setback in its EV truck production timeline. This move took many by surprise, considering the growing demand for electric vehicles and the company’s strategic shift towards EVs.

Reasons Behind the Delay

Several factors have contributed to the delay in GM’s EV truck production. Understanding these reasons is vital to gauge the implications accurately. Here are some of the key factors:

Supply Chain Disruptions

The global supply chain disruptions that emerged in the wake of the COVID-19 pandemic have affected various industries, including automotive. Component shortages, logistic challenges, and production delays have become commonplace, forcing companies like GM to reconsider their production schedules.

Semiconductor Shortages

One of the most critical factors behind GM’s delay is the shortage of semiconductors. Modern vehicles, especially EVs, rely heavily on semiconductor technology for various functions, including battery management and autonomous driving. With limited semiconductor availability, automakers face significant production constraints.

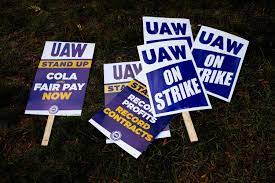

Labor and Workforce Issues

Labor disputes and workforce shortages have further exacerbated the situation. As we’ve seen in recent times, strikes, labor shortages, and skill gaps have disrupted manufacturing operations, leaving automakers struggling to maintain their production schedules.

Regulatory Challenges

In the rapidly evolving EV landscape, regulatory challenges can’t be ignored. Meeting stringent emissions standards and safety regulations demands constant adaptation. This dynamic regulatory environment can also lead to delays in production as automakers navigate compliance issues.

Implications for General Motors

The delay in EV truck production has significant implications for General Motors. As one of the major players in the industry, any setbacks have a ripple effect. Some key implications include:

Competitive Disadvantage

This delay could place GM at a competitive disadvantage in the growing EV market. Rivals may seize the opportunity to gain market share, potentially affecting GM’s long-term prospects.

Financial Consequences

Production delays typically result in financial repercussions. GM may experience increased costs and potential revenue losses due to the extended timeline.

Reputational Impact

Reputation is vital in the automotive industry. Delays can erode customer trust and brand credibility. GM must manage its public image carefully during this challenging period.

Market Share Shifts

Market dynamics can shift rapidly. As GM stalls, other automakers could increase their market share, potentially reshaping the industry landscape.

Industry-Wide Ramifications

The automotive industry at large will not remain unscathed by GM’s delay. This development can lead to broader consequences, such as:

Supply Chain Reevaluation

Automakers across the board will likely reevaluate their supply chain strategies to mitigate risks and dependencies.

Semiconductors as a Critical Resource

The semiconductor shortage issue emphasizes the need for a diversified and resilient semiconductor supply chain.

Regulatory Adaptation

Industry players may need to collaborate closely with regulators to ensure smoother compliance with evolving EV standards.

Conclusion

In conclusion, GM’s decision to delay EV truck production at its Michigan plant is a significant development in the automotive industry. It is essential for industry stakeholders to closely monitor this situation and adapt to the evolving landscape